Wir formen Die

Gründer von

Morgen.

Netzwerkevent

118. Gründergrillen

Mehr Erfahren

Mach mit!

Gewinne mit deiner Idee beim Ideenwettbewerb

Mehr Erfahren

Hör rein und lerne unsere Start-ups kennen!

Start-up Podcast

Mehr Erfahren

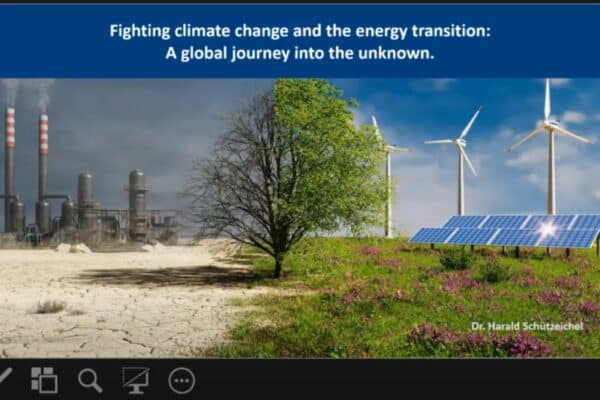

Ineratec

Tim Böltken, Philipp Engelkamp, Peter Pfeifer, Poalo Piermartini

Mehr Erfahren

Kolibri Games

Daniel Stammler, Janosch Sadowski und Oliver Löffler

Mehr Erfahren

↓

↓

DIE GRÜNDERSCHMIEDE IN ZAHLEN

5 Fakten

↓

↓

In 7 Schritten zu deinem Unternehmen

Wir begleiten auf dem

weg zum Unternehmen —

VON DER IDEE BIS ZUM EXIT.

Wir helfen dir bei der

Lerne uns kennen

Du interessierst dich für unsere Angebote, möchtest Teil unseres Netzwerks werden oder einfach schauen, wo wir uns so überall engagieren? Hier findest du mehr darüber.

AUF WAS WARTEST DU?

Vereinbare noch heute

deinen Beratungstermin

und komm vorbei!

AUF WAS WARTEST DU?

Vereinbare noch heute deinen Beratungstermin und komm vorbei!

↓

↓